I've recently undertook a plasticard project and wanted to post some words on how I work with plasticard.

Pictured above are my suggested tools.

- Exactoknife: (with plenty of fresh blades). I get the 15 blade cartridge because it provides a place other than the bottom of my foot to put used blades.

- Cutting board: I picked one up for just hobby use at a local store for a couple bucks. The razor blade really digs it up so I don't suggest using your household one.

- Scissors: I use some hospital ones because I'm a common work thief. I'd recommend some strong scissors as you can be cutting some pretty thick plastic. Also, since some time you'll be making tiny fine cuts I'd also recommend smaller ones because they are easier to maneuver.

- Sandpaper: I use all grades, but mostly fine 220 or greater. Sometimes I'm sanding large chunks of glue or large lips of plastic to get a nice square edge and I'll use the coarse paper or even my hobby files. I have a few grades on hand ranging from 150 to super fine.

- Metal ruler: Pick up a small 6" metal ruler, emphasis on metal. I use this to make straight cuts and of course to measure. I tried to free hand straight lines in the past and it is just easier to use the ruler to make sure each and every cut is exact and precise.

- Glue: Obviously, you'll need to glue stuff. I still use the normal super glue despite being able to use the plastic glue. I tried the plastic glue but didn't really like it, I'll stick to the super glue (see what I did there?) My only real point to put it on the list is that I use a lot of it when working with card. You'll see as you read why I tear through the stuff.

- Insta-set: A must when doing platicard work. However, use with caution as the catalyst reaction can get pretty hot and if you have a ton of glue in there, you can actually melt your card. I picked up a small half pint jug of this and just keep refilling the one spray bottle I have. Obviously, if I'm using a lot of glue, I'm using a lot of insta set. A jug was just over $10 and is like 10oz. The spray bottle pictured is 2oz and cost $5. Its like an elementary math story problem.

- Plasticard: Obvious, but you know that one joker out there will point it out if I don't put it on the list. I guess if I put this on my list I should put other obvious things like 'Light' and 'Oxygen' and 'ammonia mixed with bleach'

In this mini guide I'm making a piece off the warhound titan template. I printed out the entire guide with duplicates for the legs. First thing I do is I'll cut the piece out of the guide I want to make, leaving a tiny boarder. I don't need to cut right on the printed line, but leaving the board insures I don't cut the line funny and still allows me to place the template on the card conserving as much of the card as possible. Typically I don't end up with too much wasted scrap card. Also, I will generally find a 90 degree corner or at least a straight edge on the template to line up with a straight edge on the card. In the picture to the right I use the corner of the card as the corner of the template.

After cutting my template and finding the best placement I'll tape it in place with clear packaging tape. Cover the entire template, you really want to make sure it stays perfectly in place and has no chance of sliding around. After that its just a matter of cutting. I go over each line once, only scoring the card and not cutting through. Unless its a really tight corner, all you'll need to do is just score the card; not cut all the way through.

To the right is the finished scoring. You should be left with the shape of the template. Again, don't worry about having to cut through the card. If you do this you'll just end up with hand cramps, cut fingers, and aching knuckles the next day.

After you have your scored piece of card and have removed all the excess tape, (some time you'll wrap it around the back during the tap process, make sure you get that off too!) simply bend the card on the score lines being careful not to break the entire score line.

You only want to break the card along the line on the very outer boarder of the piece.

After you break out the piece you should end up with a piece of card in the layout of your original template.

Sometimes a line doesn't break evenly through the thickness of the card or where two score lines meet. To fix this, I very lightly go over the whole boarder of the piece with 220 sand paper and sand off these uneven edges until I get a straight, consistent edge. Be care not to sand too much and end up with a curved line or uneven edges.

After all my edges are even I then carefully bend the card at the inner score lines I previously left intact only to 'break' the card, and not to fully separate the sections. All I want to do is make the section have an angled edge but still be connected to the body of the piece.

With the edge still connected (this connection is very very thin, if it breaks its no biggie, its just easier if the pieces are still connected) I use the dispenser and my cutting board to make a 90 degree brace for the two sections.

When applying glue to this edge, I use two methods. The thing to keep in mind is that if you put glue on it then spray it with insta-set, the reaction heats up enough to break that little membrane of plastic holding the sections together. First way to deal with this is to put one small drop of glue in the middle and spray it. This will separate the two pieces but only at the spot where the glue is. After that is set, I'll then go over the remaining areas without concern since the original drop is holding the card in place. The second method is running a bead along the length of the bend and allowing it to dry for 10 or so seconds and then spraying insta-set on it. In this case the glue dries enough to hold the plastic in place and then the insta-set finishes the job.

I don't follow a set doctrine when gluing, I just use which ever of these two methods work best. You'll get a feel for it too. Important part is just remembering that score line staying in tact lets you have a perfect straight angle when jointing the two pieces.

Rinse and repeat. I will do the far joint next so that after it is done, I bend the middle and bring the open edges together. Remember back to geometry that if you have two opposite 90 degree angles, your adjacent angles have to be 90 degrees

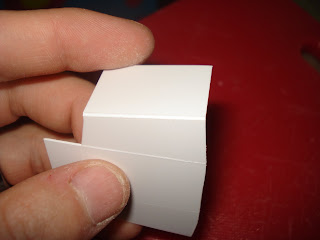

Folding the edges together you'll form your box.

Then bring up the flap. You'll want to make sure there is a bead of glue on ever edge. If not, through use and jostling the thin membranes not reinforced with glue will come apart and you'll have little slits in your edge seams.

After all the edge are glued together just go back over it with sand paper to smooth out the rough edges or corners where three seams come together.

And here is a finished product. This guide is pretty basic and you can always fill seems with green stuff and trim edges better with thin strips of card to have a more ornate look.

The sky really is the limit when it comes to building vehicles out of plasticard. Between Midwest, Evergreen and Plastruct you can find any thickness you'll need and any kind of strips you'll need. They make tubes, rods, angled pieces, thin strips, thick strips, I-beams, square tubes, ect. I'm lucky enough to have a store near by that sells it, perhaps you do too.

Let me know if you guys have any questions you come up with about working with plasticard!

Very good post, I work at a place that has a flat bed printer and x/y axis cutter and we cut a lot of plastic. I cut out all of a reaver titan and have been wondering what the best method to glue and score the secondary lines that I have printed onto the cut pieces. Thank you for this article it was very informative.

ReplyDeletewins;

ReplyDelete1. "I use some hospital ones because I'm a common work thief."

2. "I'll stick to the super glue"

3. "I guess if I put this on my list I should put other obvious things like 'Light' and 'Oxygen' and 'ammonia mixed with bleach'"

lol good article and well written

I've been following your guys' blog since I first discovered the 40k blogging community, and you never fail to impress. I've wanted a plasticard walkthrough for a while, thanks much for this.

ReplyDeleteNice post. Good tutorial on working with plasticard. Always amazes that even some very talented folks are plasticard-phobic.

ReplyDeleteHmmm... Titan... (After I finish everything else)

Really its was very interesting.

ReplyDeleteA nice tutorial for home based business of plastic products.

ReplyDelete